|

- Category: Profiles

TECHNOLOGY PROFILE 6

Artificial intelligence in the form of ChatGPT was a massive and almost instant phenomenon. One year ago – in November 2022 – OpenAI released its ChatGPT model on the internet. Within only a few days, the model had been tried by more than one million users. The release of this chatbot caught OpenAI’s competitors off-guard, and many companies had to scramble to get competing products launched.

Unfortunately, the media hype generated by the rapid uptake might have caused some decision-makers to ignore paying more attention to the rapid developments in the generative artificial intelligence landscape.

It would be a mistake for decision-makers to allocate the developments in the AI field to the IT department. These developments can change how data is used and decisions are made. Even the current AI tools enable manufacturers to unlock their data and integrate diverse business areas like logistics, manufacturing, customer service, and more..

- Category: Profiles

TECHNOLOGY PROFILE 5

A robot is a programmable machine that can complete a task typically performed by a human. Robots have different levels of autonomy, ranging from human-controlled to autonomous bots that perform tasks without external influence. The field of study focused on developing robots and automation is called robotics.

A robot is a programmable machine that can complete a task typically performed by a human. Robots have different levels of autonomy, ranging from human-controlled to autonomous bots that perform tasks without external influence. The field of study focused on developing robots and automation is called robotics.

Industrial robots are typically seen as a replacement for labour, while collaborative robots, or cobots, possess the innate ability to work in tandem with humans.

- Category: Profiles

TECHNOLOGY PROFILE 4

Augmented reality (AR) technology allows digital content to be overlayed or superimposed onto the real world. AR is only partially immersive as digital content is integrated as a layer onto the real world, whereas virtual reality is closed and fully immersive. The costs of applying augmented reality are much lower than the costs of virtual reality because AR typically combines a visual feed with a data layer; it does not involve the creation of a complete virtual world.

Augmented reality (AR) technology allows digital content to be overlayed or superimposed onto the real world. AR is only partially immersive as digital content is integrated as a layer onto the real world, whereas virtual reality is closed and fully immersive. The costs of applying augmented reality are much lower than the costs of virtual reality because AR typically combines a visual feed with a data layer; it does not involve the creation of a complete virtual world.

A major benefit of AR is that it reduces users’ cognitive load and provides technical staff access to relevant (and digitally updated) records, data and information.

- Category: Profiles

TECHNOLOGY PROFILE 3

Artificial intelligence (AI) can be described as the ability of digital systems to acquire and apply knowledge, and to autonomously execute tasks associated with intelligent beings. This includes a variety of cognitive tasks such as sensing, processing, language, reasoning, learning or even making decisions or self-correcting. AI combines sophisticated hardware and software with elaborate datasets and knowledge-based processing models to demonstrate characteristics of effective human decision-making.

It would be a mistake to think of AI as a technology of the future, because it is already used in our smartphones, on websites, in aircraft, for traffic navigation, in the finance sector, and increasingly in manufacturing.

- Category: Profiles

TECHNOLOGY PROFILE 2

Over the past 10 years, the Internet of Things (IoT) has slowly crept into the daily lives of consumers through smartwatches, vehicle tracking systems, public transport apps, home alarm systems and food delivery services. These technologies offer many conveniences, such as tracking transport schedules, parcel deliveries, the location of assets like vehicles, or local weather conditions. It takes existing expert domains, such as smart factories, process automation, flexible manufacturing and process control, and combines these with the extensive reach of internet and telecommunication technologies.

Over the past 10 years, the Internet of Things (IoT) has slowly crept into the daily lives of consumers through smartwatches, vehicle tracking systems, public transport apps, home alarm systems and food delivery services. These technologies offer many conveniences, such as tracking transport schedules, parcel deliveries, the location of assets like vehicles, or local weather conditions. It takes existing expert domains, such as smart factories, process automation, flexible manufacturing and process control, and combines these with the extensive reach of internet and telecommunication technologies.

For industry, the Industrial Internet of Things (IIOT) offers increased oversight and connectivity between different manufacturing and business processes, and closer integration with suppliers, logistics providers, warehouses, and even clients. It allows for improved efficiency and better analysis of process flows, often over large distances. At the same time, it allows for new services to be offered to clients such as predictive mainte-nance, management systems, analytical services and software updates.

At the heart of IoT technology is the capability to integrate the data streams from distributed sensors into management systems and user interfaces. While some sensors mainly collect and transmit data, other sensors could be programmed to automatically trigger programmed functions. As these different sensors and devices perform their functions, rich data is collected that allows for improved process management and efficiency, data analysis and value to be offered.

- Category: Profiles

TECHNOLOGY PROFILE 1 (Updated April 2022)

Additive layer manufacturing describes a manufacturing process in which a digitally controlled head with a laser deposits a fine layer of raw material to construct a three-dimensional object. Additive manufacturing is sometimes also called 3D printing.

Additive layer manufacturing describes a manufacturing process in which a digitally controlled head with a laser deposits a fine layer of raw material to construct a three-dimensional object. Additive manufacturing is sometimes also called 3D printing.

3D desktop printers are already available to consumers at computer retailers and hobby shops. The performance and functionality of desktop 3D printers are increasing rapidly, while the cost of ownership is falling rapidly. Desktop 3D printers usually deposit a layer of molten plastic on a bed to create a three-dimensional shape.

In the industrial domain, rapid advances are being made in the melting of metals, alloys, high performance plastics and polycarbonates using lasers. Likewise, in the medical field, different technologies are being developed that allow for the combination of cells, growth factors, biomaterials and tissue to grow organs. Additive manufacturing technologies are also used to print complex sand moulds, or to create wax moulds for investment castings. The metal objects made by 3D printed moulds are basically ready-for-use and require almost no further grinding or processing.

- Category: Profiles

COMPANY PROFILE 5

Jendamark Automation, based in Gqeberha, was the brainchild of Eastern Cape-born Quinton Uren who started working out of a garage in 1989. More than 30 years on, with Uren at the helm together with three other directors, Jendamark has grown from three employees to well over 700 worldwide. This homegrown company from the Eastern Cape now has a production facility in India and sales offices in Germany and the United States, and has become a global player delivering turnkey production line solutions to some of the world leading automobile manufacturing companies.

- Category: Profiles

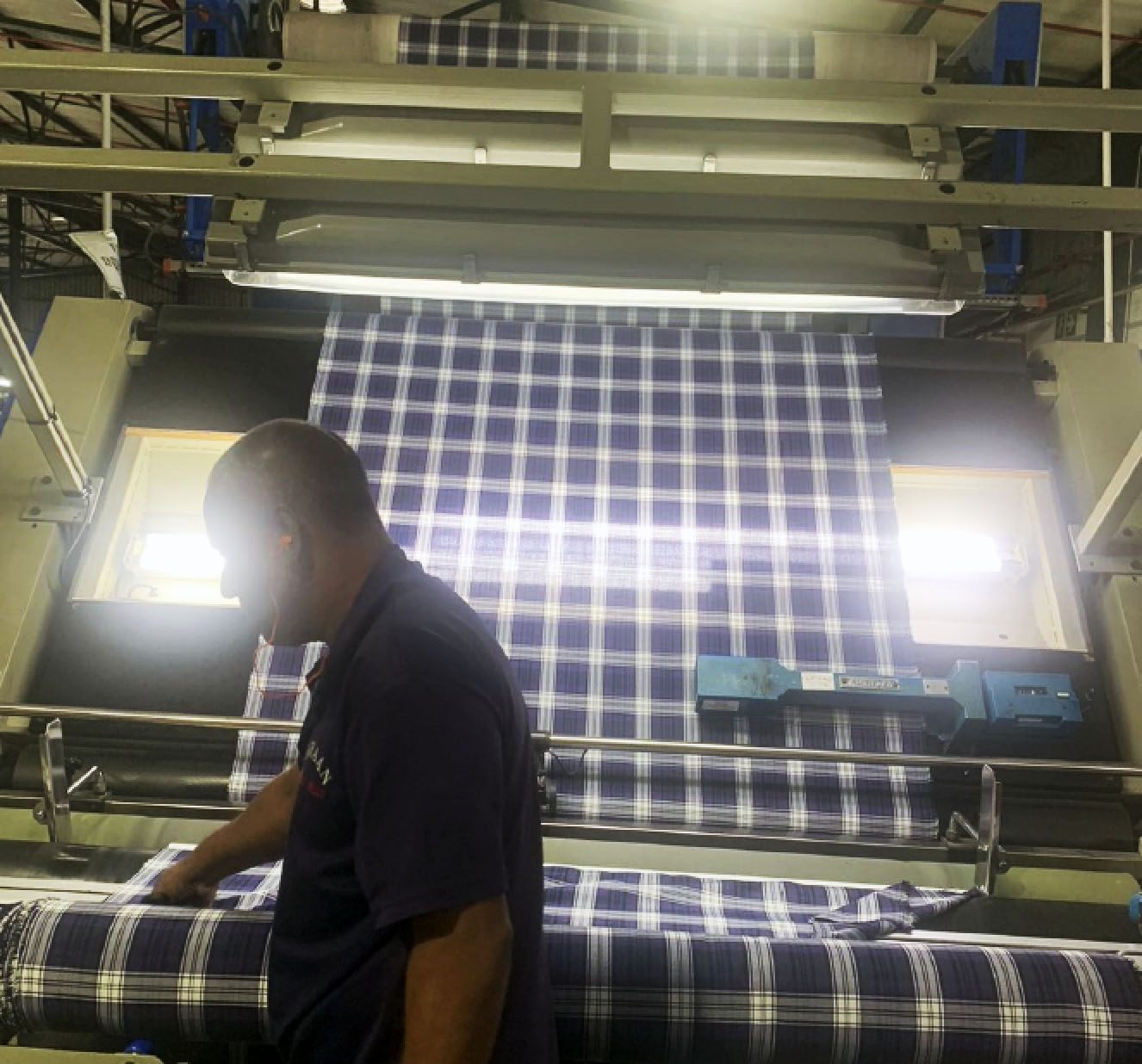

COMPANY PROFILE 3

Imraan Textile Mills – which produces woven fabric mainly for the local apparel market – is located in the hills of Mtwalume on the South Coast of KwaZulu-Natal. The Bux family became a minority shareholder of the company on the eve of the new democracy in 1994. Within a matter of years, the company, like many other textile mills, faced intense competition from the influx of cheaper imported clothing as the economy opened up to international competition in the post-1994 period. While the small-fledging company survived in part through the use of new technologies, many others closed their doors.

Imraan Textile Mills – which produces woven fabric mainly for the local apparel market – is located in the hills of Mtwalume on the South Coast of KwaZulu-Natal. The Bux family became a minority shareholder of the company on the eve of the new democracy in 1994. Within a matter of years, the company, like many other textile mills, faced intense competition from the influx of cheaper imported clothing as the economy opened up to international competition in the post-1994 period. While the small-fledging company survived in part through the use of new technologies, many others closed their doors.

- Category: Profiles

COMPANY PROFILE 2

Foundries are traditionally depicted as being dirty, dark and dangerous but the current General Manager of Hi-Alloy Castings, Dalmari Mc Queen, is focused on transforming the company into a “foundry of the future” which is digital, intelligent, clean and green. Mc Queen is an industrial engineer who has a long history of working and consulting in the foundry sector..

Foundries are traditionally depicted as being dirty, dark and dangerous but the current General Manager of Hi-Alloy Castings, Dalmari Mc Queen, is focused on transforming the company into a “foundry of the future” which is digital, intelligent, clean and green. Mc Queen is an industrial engineer who has a long history of working and consulting in the foundry sector..

- Category: Profiles

COMPANY PROFILE 1

At first glance on entering the Prestige Clothing TFG factory in Epping, Cape Town you get a sense of a traditional clothing manufacturing company. However, beyond the rows of machinists you get a glimpse of a different world emerging – a world of automated cutting machines, automated stitching machines, and increased digitalisation. It is these technological advances that have contributed to the success of this operation.

At first glance on entering the Prestige Clothing TFG factory in Epping, Cape Town you get a sense of a traditional clothing manufacturing company. However, beyond the rows of machinists you get a glimpse of a different world emerging – a world of automated cutting machines, automated stitching machines, and increased digitalisation. It is these technological advances that have contributed to the success of this operation.